Microtechnologist

This is what you will learn and work on during your training

During your first two years with us, you will work in all departments. You will learn the various process steps required to manufacture microchips in a clean room. After that, it is decided in which department you will deepen your knowledge in the third year and take the final exam.

Responsibilities

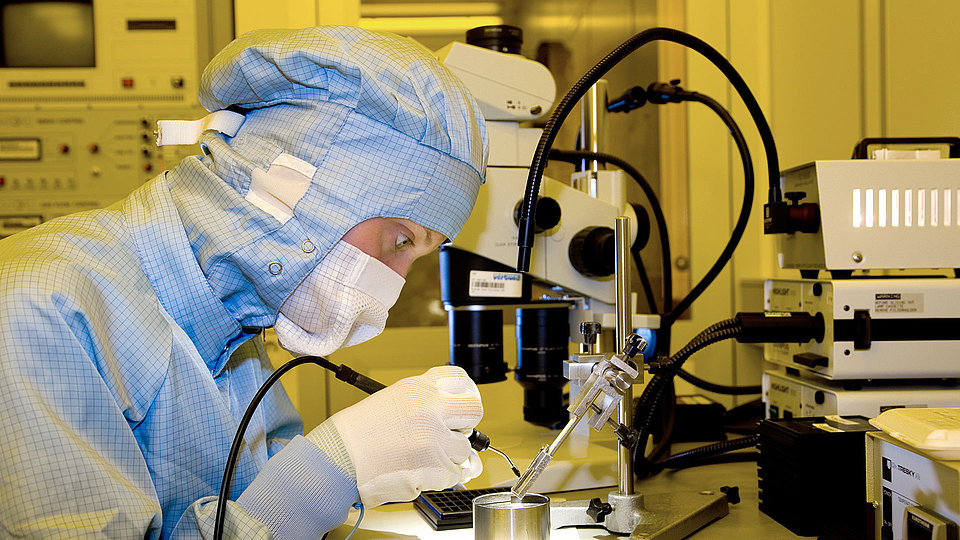

- Material technology - coating the starting material (wafer) using various techniques

- Process technology - wafer patterning by coating, varnishing, exposing, developing and etching

- Plan and perform test series

- Set up and monitor production facilities

- Review and optimize process flows.

- Produce, store and properly dispose of working materials such as process chemicals

- Evaluate measurement results on the PC

- Assemble chips and build them into systems

This is what you can expect from working with us

- 3-year apprenticeship (IHK qualification), which you can shorten by half a year if you perform well

- Mixture of theory (vocational school) and practice (institute)

- Varied work in the lab (clean room): research means trying out new things and not doing the same thing every day

- A team that supports you fully

- Excellent chances of being taken on if you complete your training successfully and fit in well with the team

- Remuneration according to TVAöD, 30 days vacation

This is what you should bring with you

- Good secondary school diploma or high school diploma - also suitable for dropouts..

- Interest in science and technology.

- Patience and Focus - you'll often be working with tweezers and a microscope on tiny micro- and nanometer-scale components.

- Manual skills

- Sense of responsibility and ability to work in a team - good coordination of the various process steps with colleagues is important!

Microtechnologists work in the semiconductor industry, in research institutions or universities. They produce things that everyone uses every day, but hardly anyone notices. Whether PCs, cell phones or airbag systems, they would all be impossible without the tiny all-rounders from microelectronics and microsystems technology. The necessary microchips are manufactured by microtechnologists. Every year, FBH offers several apprenticeships with a focus on semiconductor technology.

The training usually starts on September 1 every year