ProFIT project SAMBA

Berlin value chain for lightweight manufacturing with FBH diode lasers

In the Pro FIT project SAMBA, the Ferdinand Braun Institut, Photon Laser Manufacturing GmbH and SKDK GmbH will work together to design an innovative compact source for Additive Manufacturing (AM) based on direct-diode laser technology. This improved laser-wire-deposition processing tool will allow the fabrication of complex shapes due to its compact size, eliminate failure modes due to the absence of optical fibers and increase the efficiency by adapting the wavelength to the material absorption.

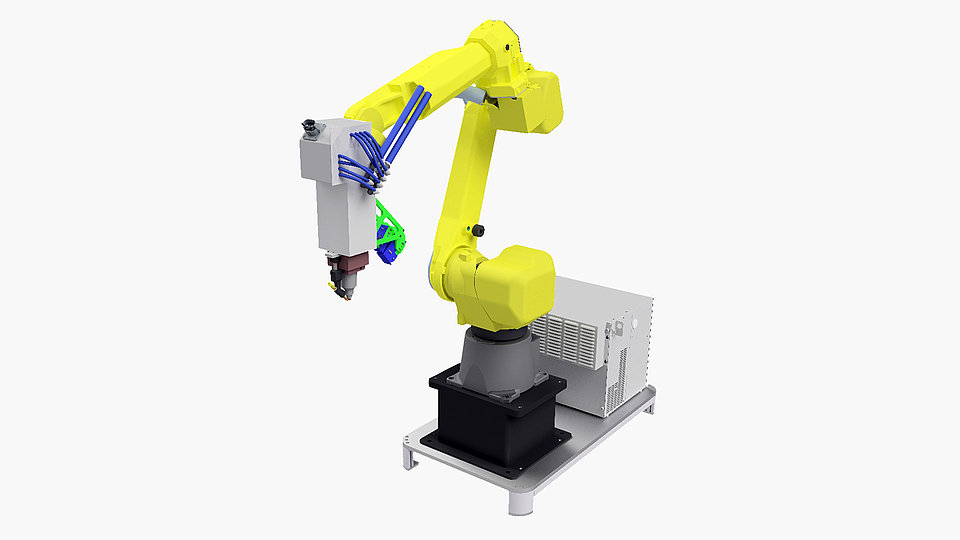

From concept to module production and demonstration, the regional collaboration covers the entire value chain. The High-Power Diode Lasers Lab and the Prototype Engineering Lab will develop high-performance kilowatt direct diode laser modules at 780 nm to target the absorption peak of aluminum. Photon Laser Manufacturing will equip the laser module with a wire feed unit and the necessary infrastructure to monitor and control the process. The complete process head will then be integrated onto a robotic arm by SKDK for the automation of the process. To validate the laser-wire-deposition process with this new SAMBA process tool, the fabrication of side panels of high-speed trains with significantly reduced weight will be demonstrated.

SAMBA is an "AMBER ProFIT Innovation" project and is co-financed from 2023 - 2024 with funds from the European Fund for Regional Development (ERDF) Berlin.

![[Translate to English:] Logo von AMBER](/fileadmin/_processed_/e/e/csm_SAMBA_Amber_Logo_23beff7de9.webp)

![[Translate to English:] SKDK IT-Engineering](/fileadmin/_processed_/e/a/csm_SAMBA_SKDK_Logo_b8ea9d82a0.webp)

![[Translate to English:] Logo von Photon Technology in Motion](/fileadmin/_processed_/2/e/csm_SAMBA_Photon_Logo_5d88c72eb5.webp)