Heating with Microwaves – KuBiMikE

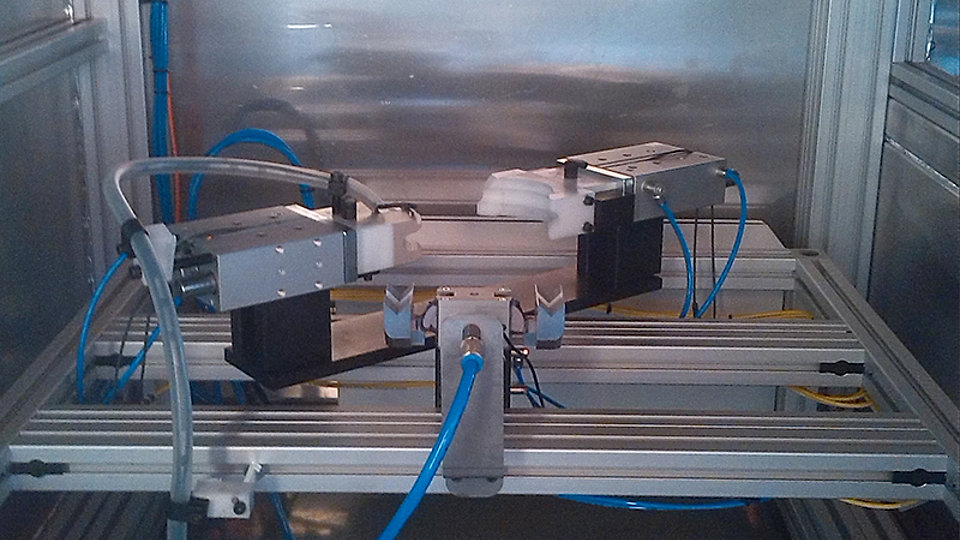

In the ProFIT project KuBiMikE (Kunststoff-Biegeverfahren mit Mikrowellen-Erwärmung), the Ferdinand-Braun-Institut is cooperating with the company mobitec - Kottmann + Berger GmbH to develop a microwave-driven plastic pipe bending system. The SME based in Baden-Württemberg is establishing a branch in Berlin to implement this innovative concept.

The novel process is targeted at meeting the demands of the plastics industry for environmentally friendly and recyclable materials. At the same time, they must meet application-specific requirements such as high melting temperature and high mechanical stability. In addition, the energy consumption to process these materials is to be reduced. Conventional technologies use hot air or steam to bring plastics to melting temperature.

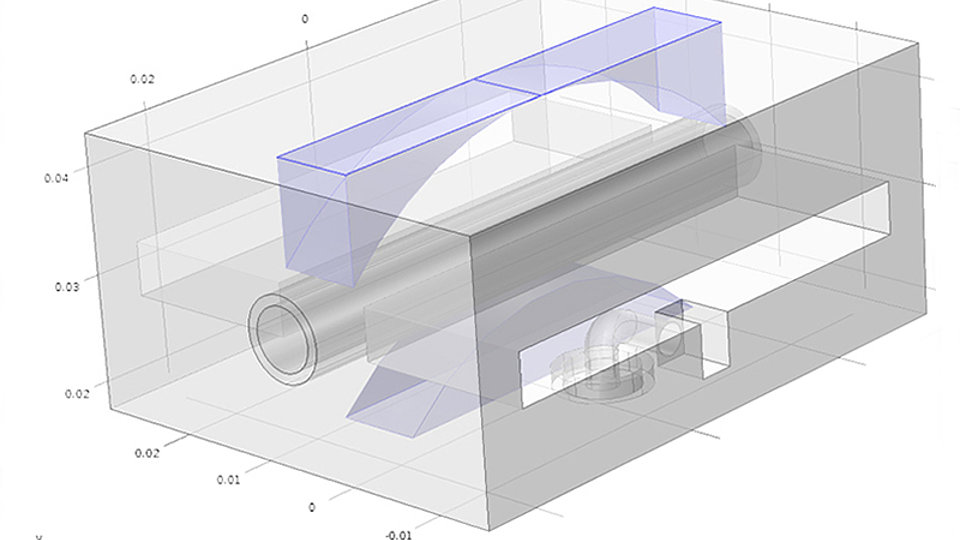

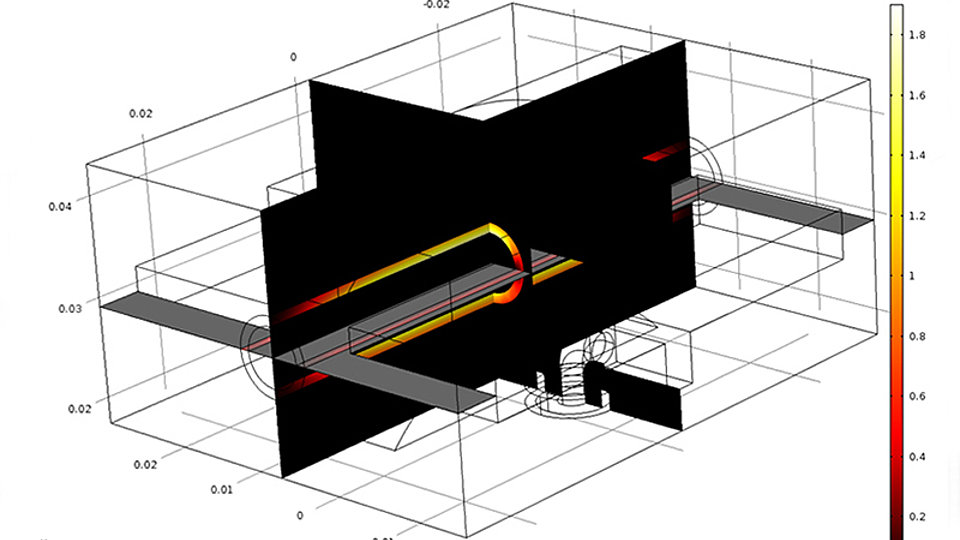

In the KuBiMiKE cooperation project, plastics are to be heated in the microwave field, which is confined to the areas that are to be formed. This should reduce energy consumption by a factor of up to ten. FBH's research work in the project focuses on special microwave resonators with predefined geometry for field confinement. For this purpose, simulations of the field and temperature distribution along with experimental investigations on the heating of the plastics will be carried out.

The joint ProFIT project KuBiMikE has been funded by Investitionsbank Berlin (IBB) through the European Fund for Regional Development since December 2019 with about 400,000 euros over a period of three years.