High-power laser system for Additive Manufacturing and further new developments at Laser World of Photonics

Once again, the Ferdinand-Braun-Institut, Leibniz-Institut für Höchstfrequenztechnik (FBH) will present its complete range of services at Laser World of Photonics in Munich from June 27 - 30, 2023 – from design to chips to modules and systems. At the Berlin-Brandenburg joint booth A2.421, FBH will showcase its diode lasers for applications in space, communication, medical technology, material processing, and quantum technology. Additionally, the institute will exhibit an irradiation system with optimized 233 nm UVC LEDs. This can be used to render multi-resistant pathogens and corona viruses harmless directly on the skin without damaging it.

FBH will present space-compatible developments and selected key components for quantum technology simultaneously in the World of Quantum halls at booth A1.231 of Research Fab Microelectronics (FMD). The institute will also attend the associated CLEO Europe conference and Laser World of Photonics Application Panels, where they are represented with more than 20 scientific contributions.

Expertise in high-power diode lasers – demonstrated in the system

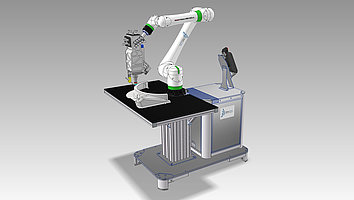

At the Berlin-Brandenburg booth, the institute and its partner companies Photon Laser Manufacturing and SKDK will demonstrate for the first time a flexible robotic arm with integrated laser beam source for Additive Manufacturing in lightweight construction. The kilowatt-class direct diode laser system features an unusual wavelength of 780 nm, which significantly improves efficiency in the fabrication of customized parts using laser wire deposition. Due to the increased absorption, this applies in particular to the production of aluminum-based structures. Among other things, this will be used to manufacture customized side walls of high-speed trains with significantly reduced weight. Thanks to the compact size of the laser system, complex components can be manufactured even in very confined spaces. In contrast to established processing tools, it operates without optical fibers, so there is no risk of system down-time due to fiber breakage.

The basis of this and other laser systems for high-power applications are FBH's diode laser stacks. They consist of innovative vertically stacked diode lasers that can be scaled up to kilowatt power levels. These diode laser sources are used as pump sources in material processing, free-space communication, printing, and medical technology – and increasingly also directly. In parallel, FBH continuously advances the laser properties at chip level, aiming for higher power, efficiency, and beam quality.

Researchers at the Ferdinand-Braun-Institut have realized diode lasers with 70 % efficiency at 70 W output power from a single emitter. The edge emitters with a wavelength of 915 nm are needed for pumping fiber lasers and direct use. They achieve higher powers due to the extremely wide emission apertures of 1.2 mm. The high efficiencies are based on advanced, highly vertical asymmetric epitaxial layer structures. FBH's Buried-Regrown-Implant-Structure (BRIS) technology allows a lateral periodic oxygen implantation layer to be created near the active region of the single emitter. This ensures emission within a narrow angle.

High-performance pulse laser sources – from LiDAR to two-photon polymerization

FBH develops pulse laser sources with tailored properties for various applications. The integrated laser drivers are realized at the institute as well. Among the developments are high-power pulse laser sources for line scanners in the field of automotive LiDAR to detect objects three-dimensionally. These laser sources are based on diode laser bars with 48 emitters featuring a pulse peak power of 2 kW for 8 ns long pulses. They deliver fast laser pulses that are reflected by objects they encounter.