Improved thermal management for terahertz quantum-cascade lasers

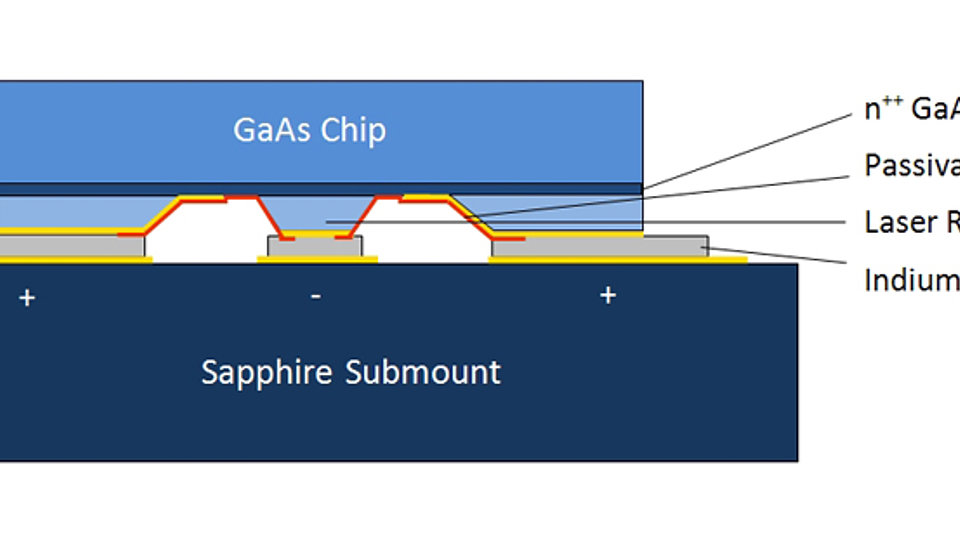

Fig. 1. Schematic cross-section of chip-on-submount assembly for epitaxial-side heat sinking (not to scale).

Semiconductor-based quantum-cascade lasers (QCLs) for terahertz generation are compact and narrowband sources for terahertz (THz) radiation. They are good candidates for various applications such as imaging, wireless communication, spectroscopy, and astrophysics as well as biological, atmospheric, and medical sciences.

A joint project with Paul-Drude-Institut für Festkörperelektronik (PDI), German Aerospace Center (DLR), Humboldt-Universität zu Berlin, and eagleyard Photonics aims at developing a technology basis for the commercialization of THz QCLs. In a first step, implementation of tunable THz QCLs in the spectrometer GREAT (German Receiver for Astronomy at Terahertz Frequencies) for space- and airborne missions, such as SOFIA (Stratospheric Observatory for Infrared Astronomy), is in focus. Currently, the operating temperature of THz QCLs in continuous wave (cw) operation is considerably below room temperature. Thus, the operation expense necessary for cooling is still an obstacle for commercial viability of such THz sources. Therefore, further advances toward room temperature operation are obligatory.

At FBH, benefits from efficient heat extraction by epitaxial-side, as opposed to substrate-side, heat sinking are explored. Although such kind of mounting scheme is well established in high-power diode laser assembly, it has not been developed for THz QCLs so far. We realized an epitaxial-side (epi-down) mounting scheme for GaAs/AlxGa1-xAs THz QCLs on sapphire submounts using indium solder. The stressless assembly provides efficient heat dissipation at cryogenic temperatures and high stability against thermal cycling. The submounts were fabricated in a wafer-level process from polished 2" sapphire substrates. Indium solder was deposited by an optimized evaporation process to obtain very smooth layers with good wetting properties for subsequent soldering.

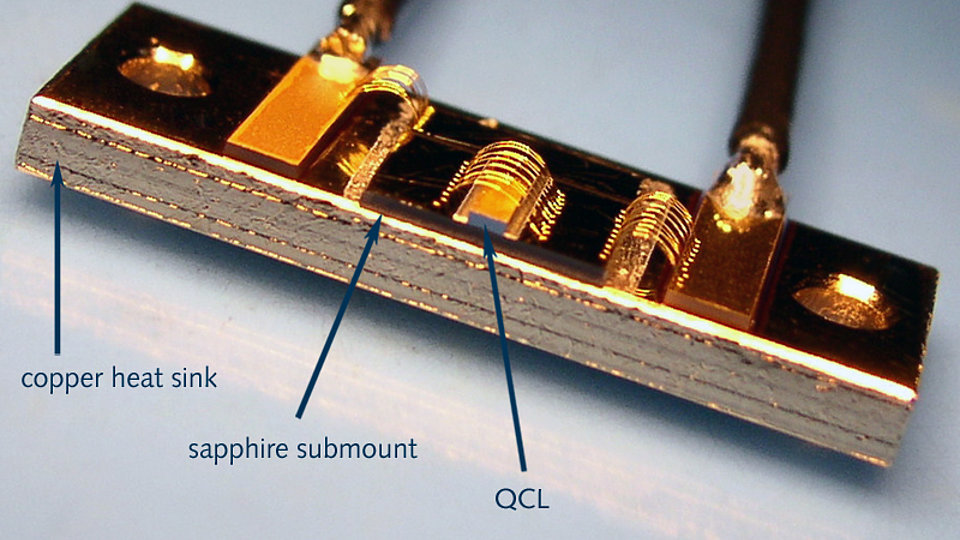

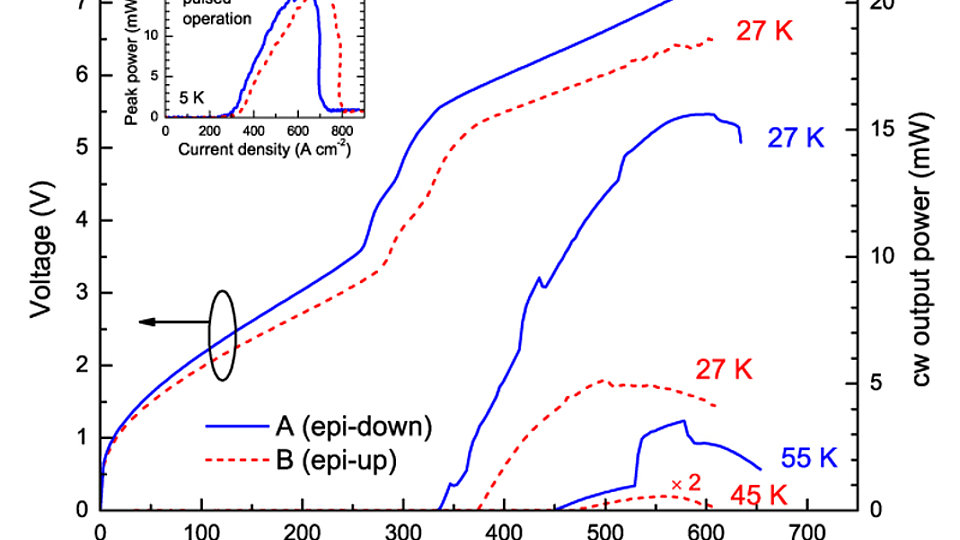

The GaAs/AlxGa1-xAs QCL structures with an Al content of x = 0.18 were grown by molecular beam epitaxy at PDI. Processing of single-plasmon ridge waveguide structures was performed at FBH. The wafers were cleaved into individual QCL chips that were soldered with their epitaxial-side onto submounts. A cross-section of the resulting chip-on-carrier assembly is schematically shown in Fig. 1. Finally, the chip-on-submount assemblies were soldered with In/Sn onto copper heat sinks (Fig. 2). The laser emits in the range of 3.1 ‑ 3.3 THz, exhibiting single-mode emission close to the threshold. Fig. 3 exemplarily depicts the light-current-voltage (LIV) characteristics for cw operation of lasers in two mounting configurations, epi-down (stripe A) and epi-up (stripe B). At the same heat-sink temperatures, the epi-down mounted sample always achieves significantly larger levels of cw output power than the epi-up configuration. In cw operation the maximum operating temperatures of samples A and B are 55 K and 45 K, respectively. In pulsed mode both lasers achieve an output power of 15 mW at 5 K as well as a similar maximum operating temperature of about 95 K. Thus, the larger output power and the larger maximum operating temperature of sample A during cw operation are clearly a consequence of the improved thermal management by epi-down mounting. The larger operating voltage, and hence a larger Ohmic heating, in case of epi-down mounted lasers is subject of current investigation and improvements of layouts are in progress.

The work is supported in part by the European Commission through the ProFIT program of the Investitionsbank Berlin.

FBH research: 04.03.2013