The impact of AlN templates on strain relaxation mechanisms in MOVPE growth of UVB-LED structures

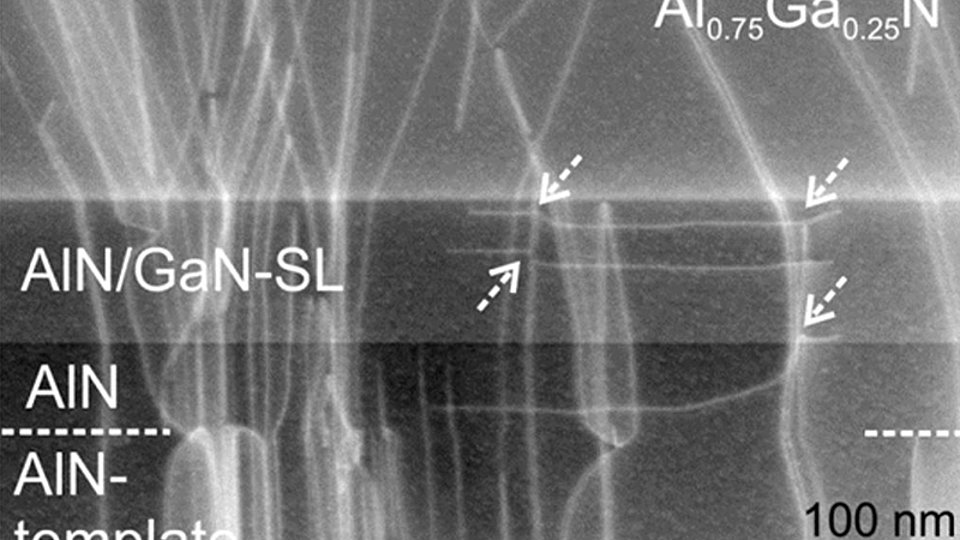

Fig. 1: Exemplary cross-sectional image of lower part of UVB-LED structure on AlN template with TDD of (4 ± 0.2) x 109 cm-2: ADF STEM showing formation of horizontal dislocation lines in AlN/GaN superlattice and strong TD inclination in subsequently grown AlGaN (viewed in [11-20]AlN projection) [3].

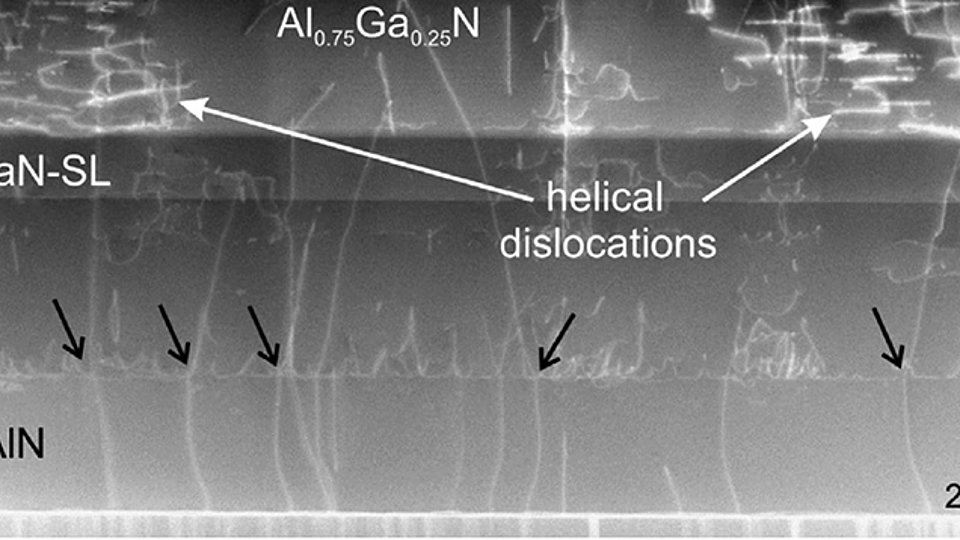

Fig. 2: ADF STEM cross-sectional image of the first layers of a UVB-LED structure grown on HTA-AlN template with TDD ~ 1 x 109 cm-2: black arrows / lines – defect behavior at the template interfaces between HTA-AlN and MOVPE AlN overgrown layers; white arrows – defect formation in Al0.75Ga0.25N layer on AlN/GaN-SL [3].

Light emitting diodes (LEDs) for the ultraviolet (UV) spectral region can be used for detection of bacteria and disinfection of surfaces, air and water – for example to avoid infection with COVID 19. This requires AlxGa1-xN based LED heterostructures with high efficiency and long lifetime. One precondition for that is a low threading dislocation density (TDD) in the emitting area of these structures, because dislocations act as non-radiative recombination centers. Due to the lack of inexpensive, transparent native AlN substrates nearly all UV-LEDs are grown on AlN/sapphire templates. For UVC-LEDs with high Al-content above x = 0.6 pseudomorphic growth on such a template is possible, and TDD reduction of the template by high temperature annealing (HTA) [1, 2] allows for high device efficiency.

For UVB-LED structures, the Al-content of the (In)AlGaN layers of the active region is below 0.3 making pseudomorphic growth on AlN templates impossible due to the resulting high compressive strain. To avoid the formation of defects in the active region of the LED the underlying AlGaN layer needs to be simultaneously relaxed and of good crystalline quality so that the active region can be grown pseudomorphically onto this AlGaN base layer.

Strain relaxation mechanisms in InAlGaN-based UVB-LED structures on different AlN/sapphire templates grown by MOVPE at FBH are analyzed by combining macroscopic in situ reflectivity and curvature data with transmission electron microscopy revealing the formation and annihilation of dislocations. In particular, the impact of dislocation density, surface morphology, and lattice constant of the AlN/sapphire templates is studied. It was found [3] that for MOVPE-grown AlN/templates with TDDs in the range of 3 × 109 cm−2 and different surface morphologies strain relaxation takes place mostly via conventional ways, such as inclination of threading dislocation lines and formation of horizontal dislocation bands (Fig. 1). In contrast, a TDD reduction in the AlN template down to 1 × 109 cm−2 by HTA, which is accompanied by a reduction of the lattice constant, leads to drastic changes in the structure of subsequently grown AlGaN layers, e.g., occurrence of helical dislocations and formation of macrofacets on the surface (Fig. 2). For the growth of strongly compressively strained AlGaN layers for UVB LEDs the relaxation mechanism is mainly influenced by the TDD and the lattice constant of the AlN template.

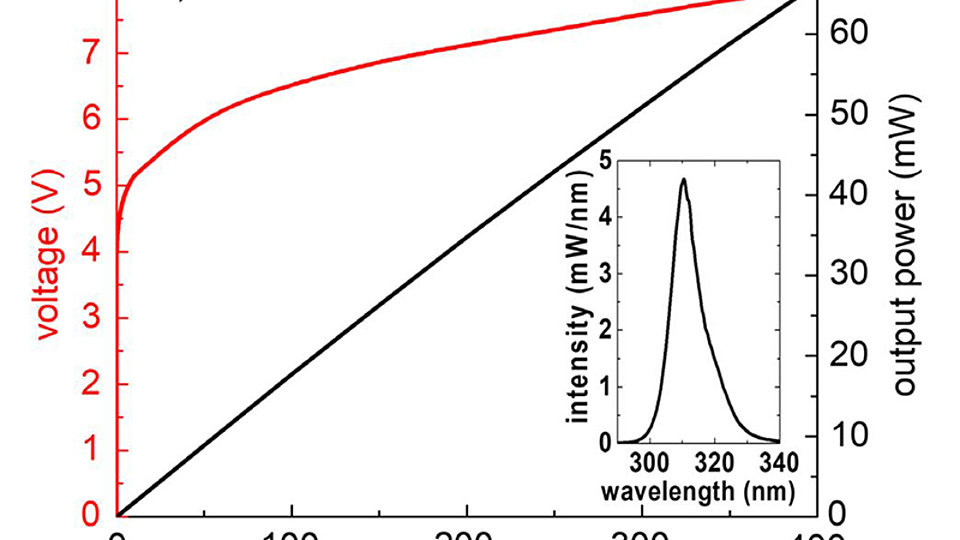

By optimizing the MOVPE growth condition of InAlGaN on AlN/sapphire templates with TDDs around 3 × 109 cm−2 it was possible to relax the compressive strain and to reduce the TDD of the emitting layer down to 1 × 109 cm−2. That gives the possibility to realize reliable LEDs emitting at 310 nm with optical output powers of 67 mW at 400 mA, (Fig. 3). Further improvement in LED performance requires a further decrease in TDD.

FBH has developed HTA AlN/sapphire templates [4] with TDDs in the low 108 cm-2 range. Adaptation of the MOVPE growth of UVB LEDs onto such templates, especially with respect to strain relaxation, is under way. Understanding strain relaxation mechanisms is important in order to leverage the advancements in AlN template technology.

The study was partially supported by German Federal Ministry of Education and Research (BMBF) through the consortia project "Advanced UV for Life" under contracts 03ZZ0130A, 03ZZ0134C, 03ZZ0130B and 03ZZ0134B.

Publications

[1] H. Miyake, G. Nishio, S. Suzuki, K. Hiramatsu, H. Fukuyama, J. Kaur and N. Kuwano, “Annealing of an AlN buffer layer in N2–CO for growth of a high-quality AlN film on sapphire”, Appl. Phys. Express 9, 025501 (2016).

[2] N. Susilo, E. Ziffer, S. Hagedorn, L. Cancellara, C. Netzel, N. Lobo Ploch, S. Wu, J. Rass, S. Walde, L. Sulmoni, M. Guttmann, T. Wernicke, M. Albrecht, M. Weyers, and M. Kneissl, "Improved performance of UVC-LEDs by combination of high-temperature annealing and epitaxially laterally overgrown AlN/sapphire", Photonics Res., vol. 8, no. 4, pp. 589-594 (2020).

[3] A. Knauer, A. Mogilatenko, J. Weinrich, S. Hagedorn, S. Walde, T. Kolbe, L. Cancellara, and M. Weyers, "The Impact of AlN Templates on Strain Relaxation Mechanisms during the MOVPE Growth of UVB-LED Structures"

Cryst. Res. Technol., vol. 55, no. 9, Special Issue: Dedicated to Prof. W. Neumann on his 75th Birthday, pp. 1900215, doi:10.1002/crat.201900215 (2020).

[4] S. Hagedorn, S. Walde, A. Knauer, N. Susilo, D. Pacak, L. Cancellara, C. Netzel, A. Mogilatenko, C. Hartmann, T. Wernicke, M. Kneissl, M. Weyers, “Status and Prospects of AlN Templates on Sapphire for Ultraviolet Light-Emitting Diodes”, Phys. Status Solidi A 2020, 217, 1901022 (2020).

[5] T. Kolbe, A. Knauer, J. Rass, H. K. Cho, A. Mogilatenko, S. Hagedorn, N. Lobo Ploch, S. Einfeldt, M. Weyers, “Improved Efficiency of Ultraviolet B Light‐Emitting Diodes with Optimized p‐Side”, Phys. Status Solidi A 2020, 2000406. doi.org/10.1002/pssa.202000406