Hybrid Micro-Integration

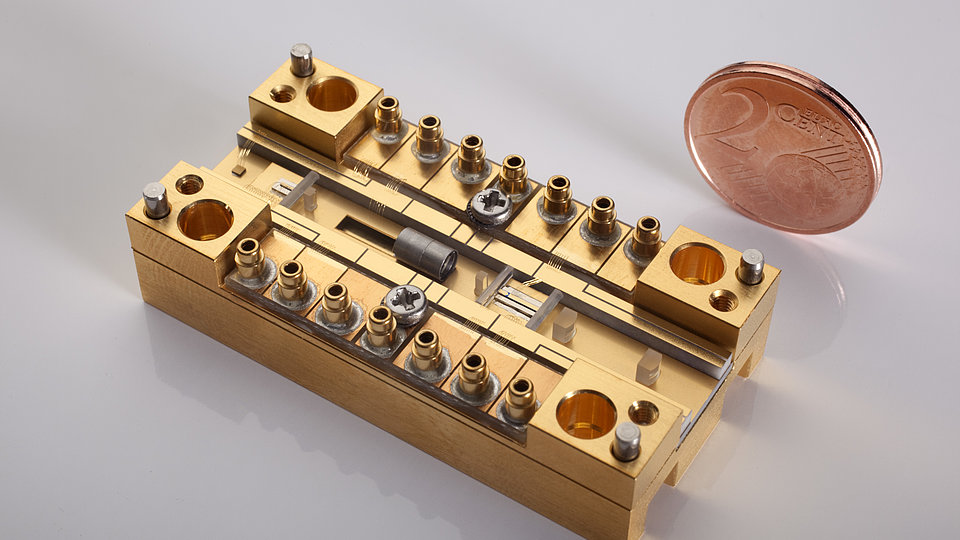

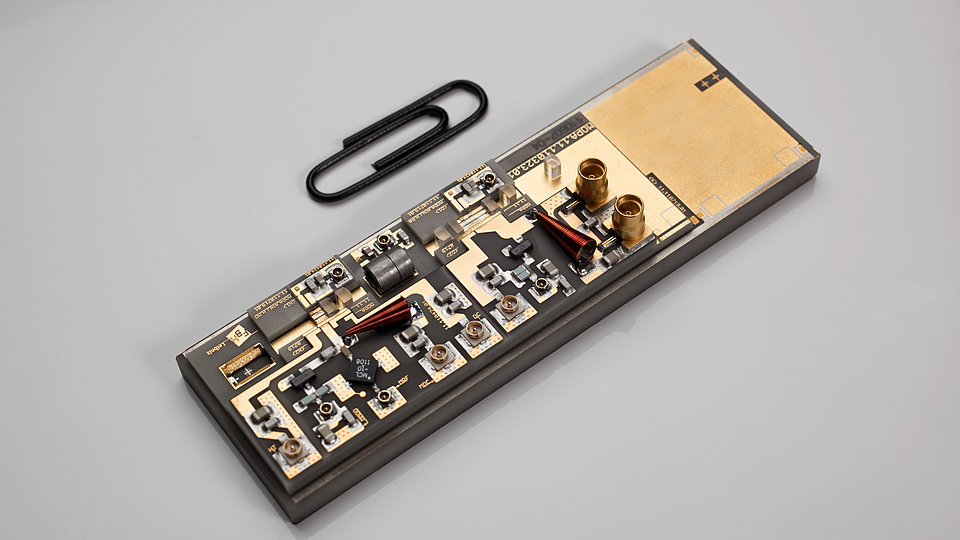

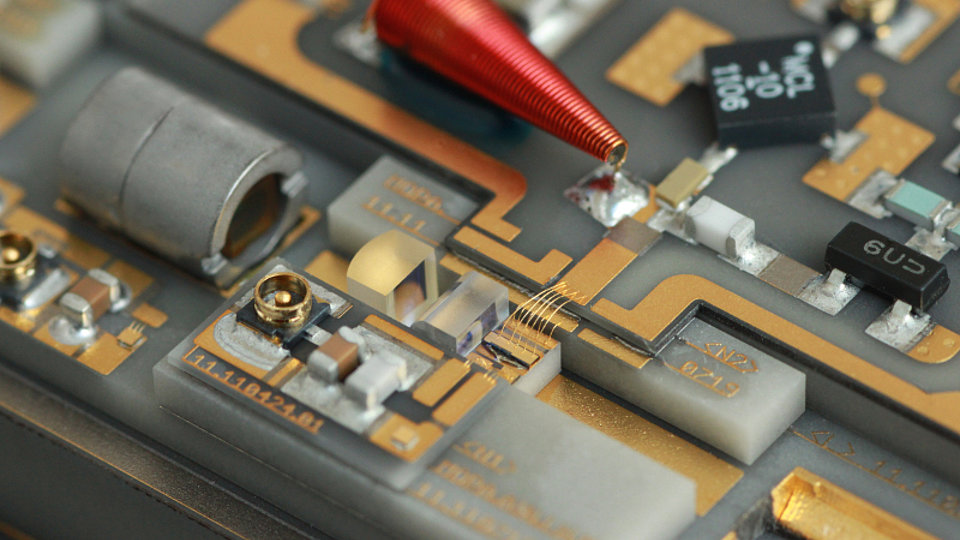

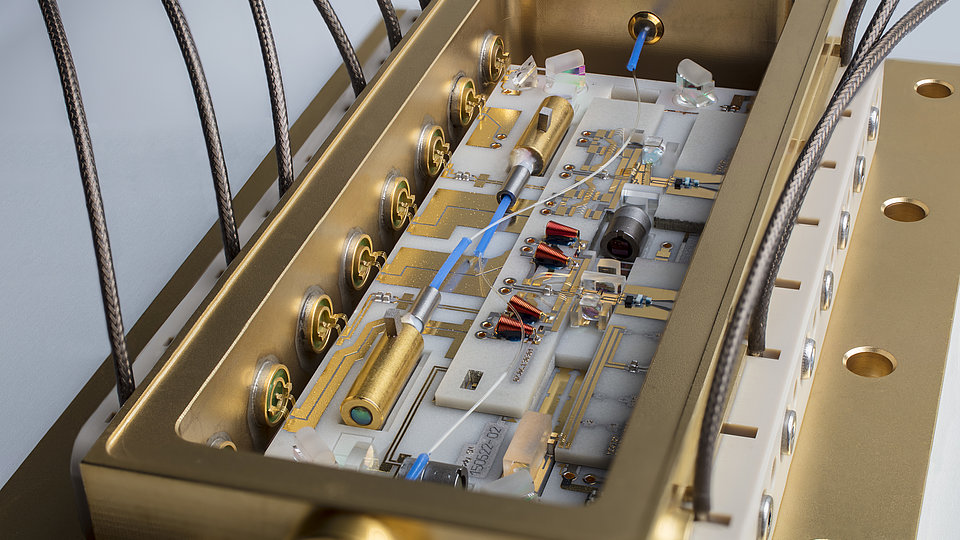

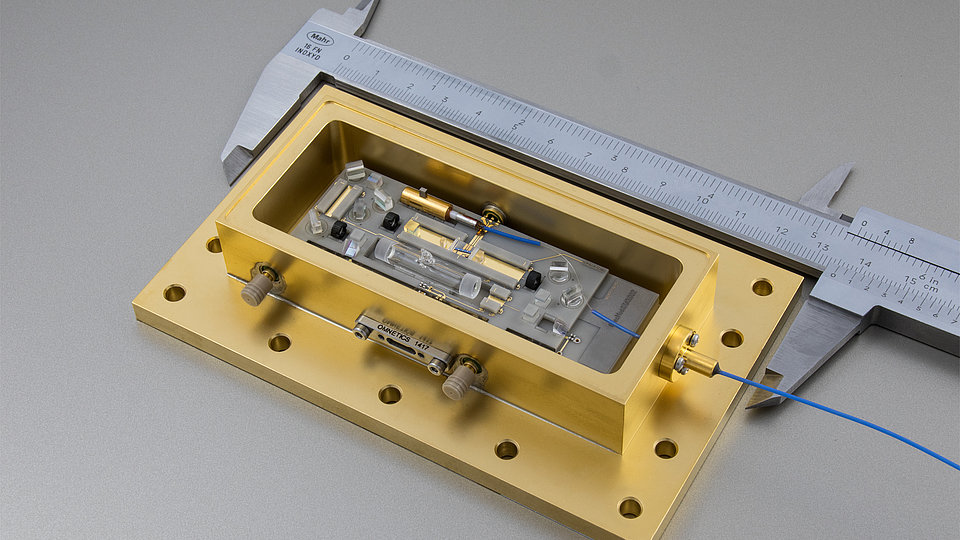

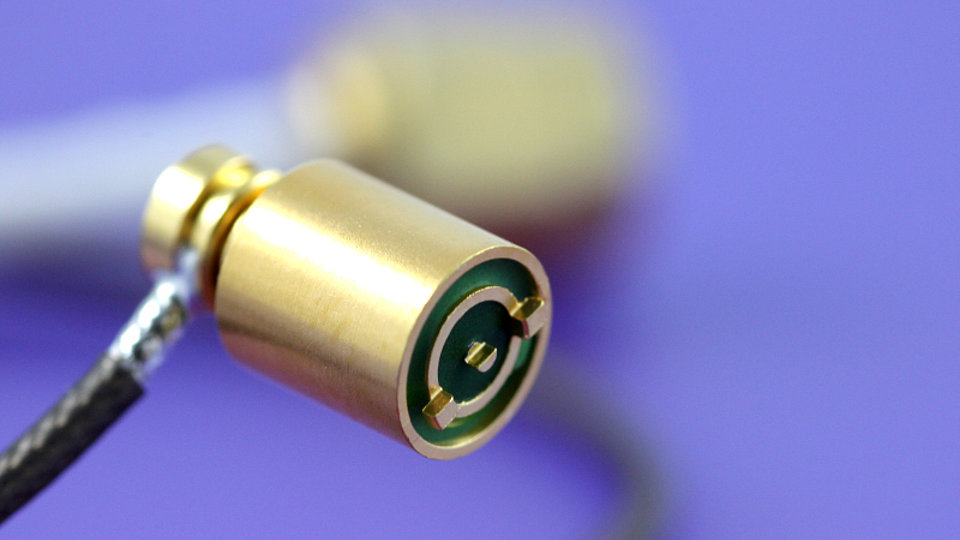

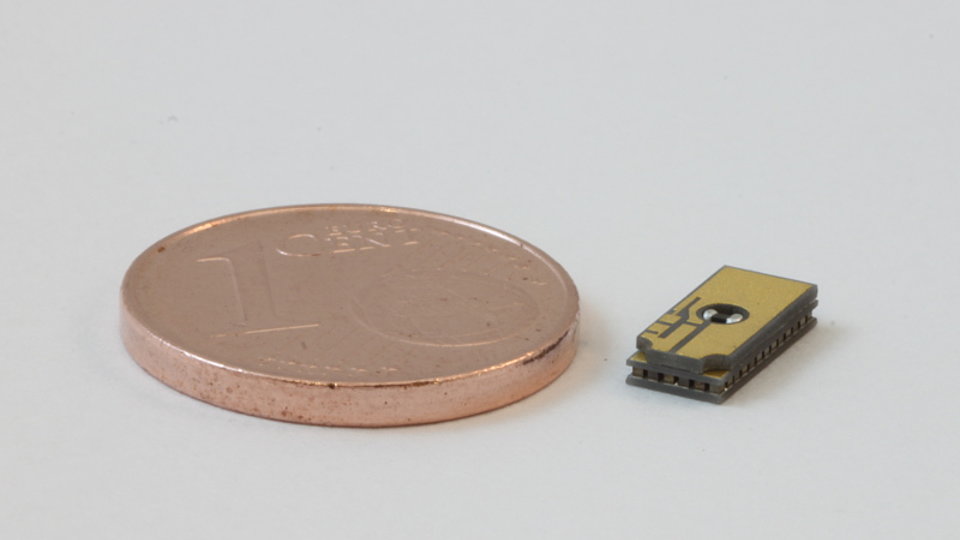

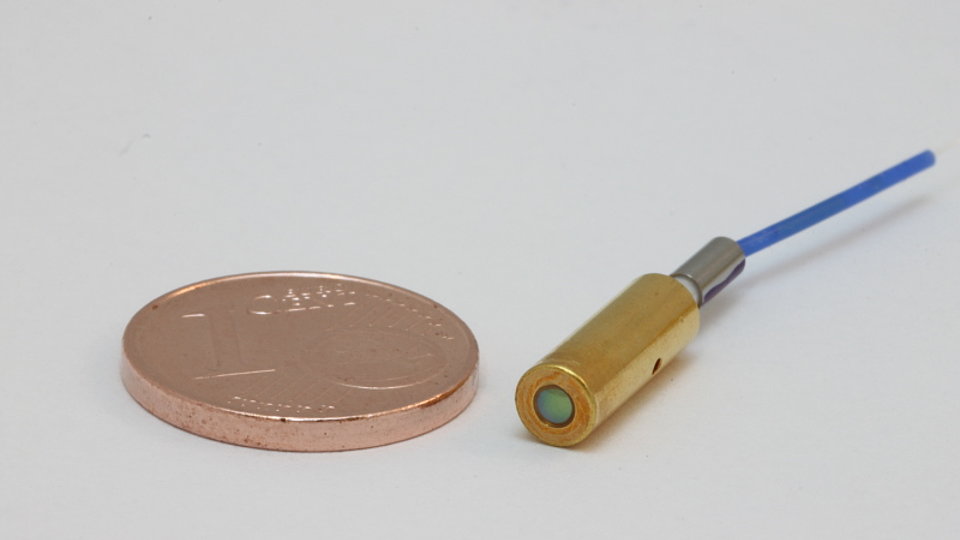

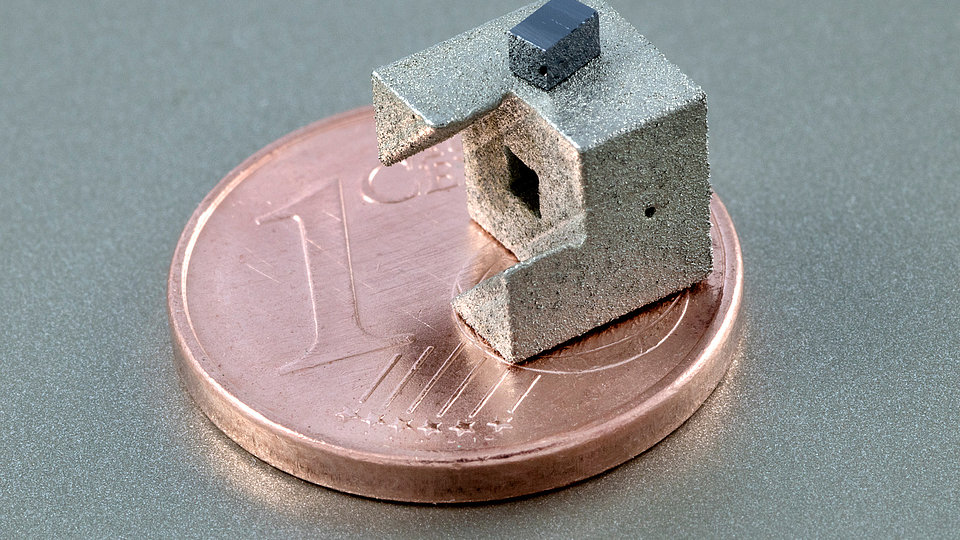

We turn the design of our photonic modules into very compact and robust hardware by utilizing our proprietary hybrid micro-integration technology. It is based on solder and adhesive bonding of electronic, opto-electronic, micro-mechanical and micro-optical components with ultra-high precision to carriers or very stable miniature optical benches. Our activities cover the development of proper robotic integration facilities that allow for simultaneous active alignment of multiple components with nm-resolution, the development of assembly processes, the acceptance tests for all critical components, the actual assembly, the validation of the electro-optic performance of the photonic modules and, finally, integration of the photonics modules at our partner's premesis. Depending on the project requirements we establish proper product assurance measures, specifically for the assembly of space hardware.

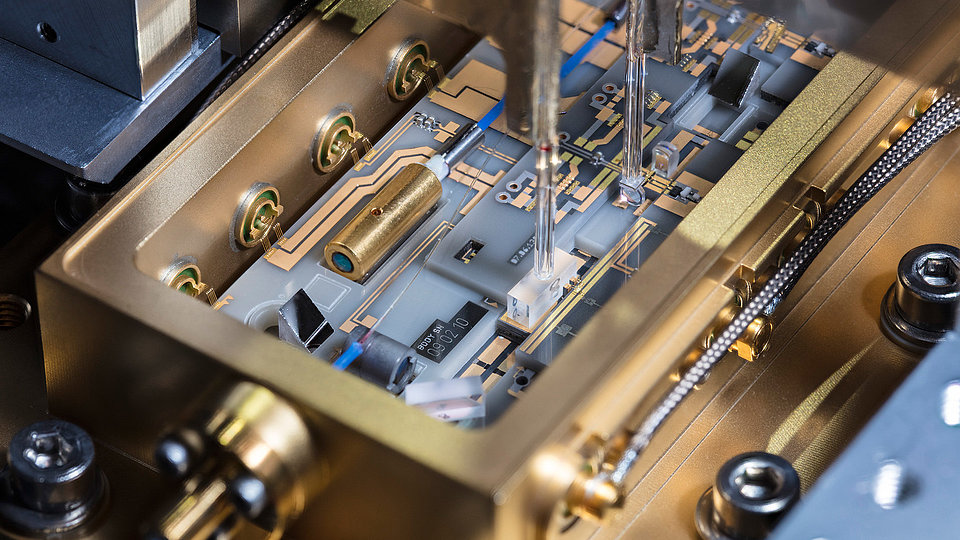

The robotic integration facility is based on piezo-driven, ultra-high resolution (1 nm, 1 µrad) manipulators. We currently operate setups that handle up to four components simultaneously and control the position and orientation of the latter in 18 degrees of freedom in an ISO 5 class environment. To find the optimal aligment of a set of miniature components, their positions and orientations are varried simultaneously and specific parameters, e.g. optical power, polarization state, optical emission spectrum or optical phase noise are monitored. After finishing the alignment, the optical components are adhesively bonded with UV-curing or hybrid adhesives to a miniature optical bench.

We continuously refine our micro-integration setup and processes to improve quality and reliabilty of the photonic modules. Proper measures include partial automation, specifically the simultaneous alignment of multiple degrees of freedom based on AI optimization methods, and integration of collaborative robots into the integration facility.

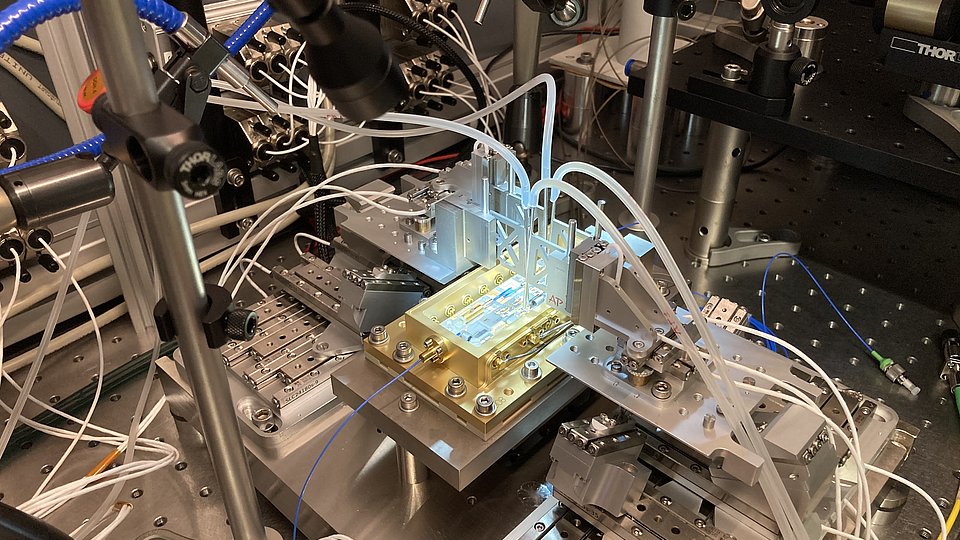

Tele-robotic facility used for the micro-integration of photonic modules

Video showing an award winning tele-robotic assembly facility, which is currently under development. It is based on a combination of four ultra-high resolution robots (not shown) providing nanometer and microdegree alignment resolution, and four high-resolution industrial robots that can operate various tools - from stereo-microscopes to nanoliter dispensers for adhesives.

A tele-robotic integration facility currently under development by FBH and Robo Technology employs a human-centric operation approach based on industry 5.0 concepts: key component of the system is a digital twin for the setup and the hardware to be assembled. The digital twin is used by a human operator to configure the robotic setup, to optimize the scene, and to interactively plan and pre-validate robotic actions. An advanced human-machine interface based on, for example, AR, gesture recognition and voice control, 3D-displays, and a haptic interface tool with force feedback, allows for intuitive (bi-directional) interaction between the human operator and the robotic facility. This approach guarantees maximum flexibility and agility required for R&D and small quantity production.