8” wafer process line upgrade streamlines chip handling at FBH

The FBH process line has achieved a significant milestone by upgrading to 8” wafer frames, now extending its advanced capabilities to the mounting and assembly department. This upgrade addresses critical needs in manual and automatic chip handling, enhancing efficiency and precision in the production process.

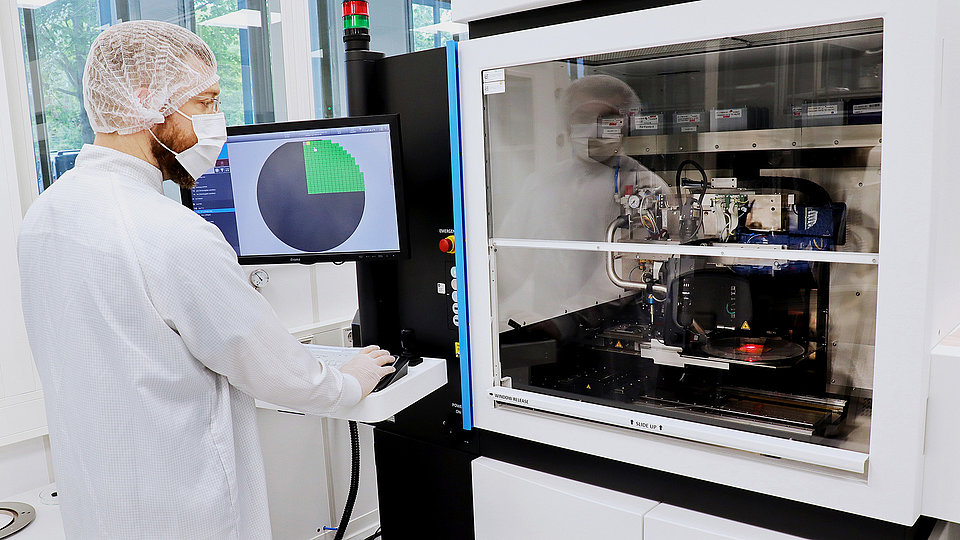

To facilitate this transformation, the department has integrated advanced equipment, including an upgrade of the automatic die-bonder (Femto 2 from Finetech) and a newly acquired manual picker (T-5300-W from Tresky).

The upgraded die-bonding machine now supports 6” and 8” dicing frames as well as grip rings for 5” wafers. Its versatility accommodates various chip sizes, wafer materials and dicing foils, including classic saw foils and laser dicing foils. Its capsulated design enables us to process even dust- and handling-sensitive chip materials with a focus on maximum yield, providing a robust solution for maintaining our high-quality standards.

Complementing this is the new pick-and-flip station, which improves our processes by ensuring safe and precise manual chip handling after direct picking on the same machine. This capability includes flipping and placing chips for applications that do not require the use of soft solder or where soldering takes place at a later stage. Additionally, its integrated dispenser simplifies the manual application of glue or solder paste in intricate module structures. This advancement supports the increasing complexity of our projects, such as 3D integration for laser and high-frequency applications.

The upgrade significantly enhances the department’s capabilities, addressing previous limitations and paving the way for more sophisticated and reliable chip assembly processes. The improved manual and automatic handling systems not only streamline production but also ensure higher precision and adaptability to various technological requirements for UV-LED mounting, THz components, and power device modules.