Approaches for higher power in GaAs-based broad area diode lasers

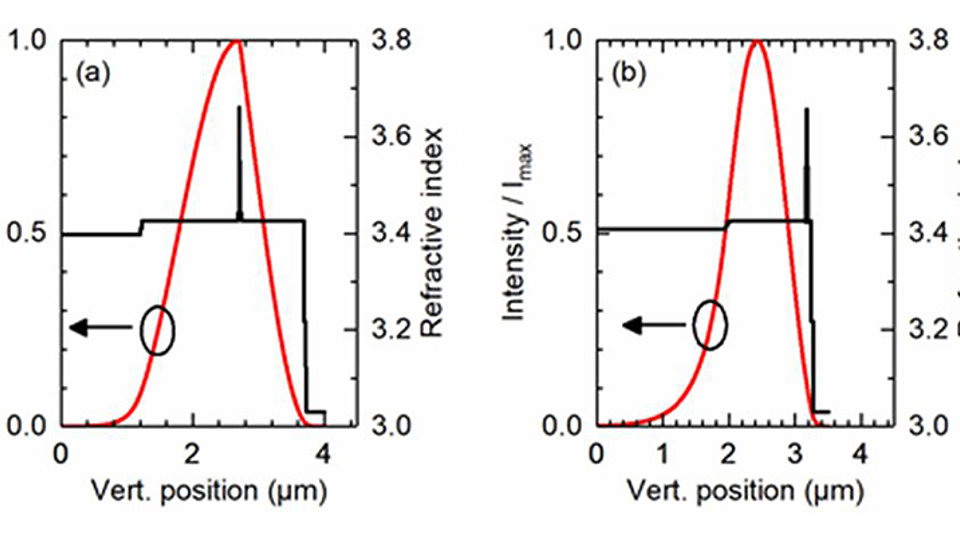

Fig. 1: Exemplary refractive index and corresponding optical field profile for (a) ASLOC and (b) EDAS epitaxial designs.

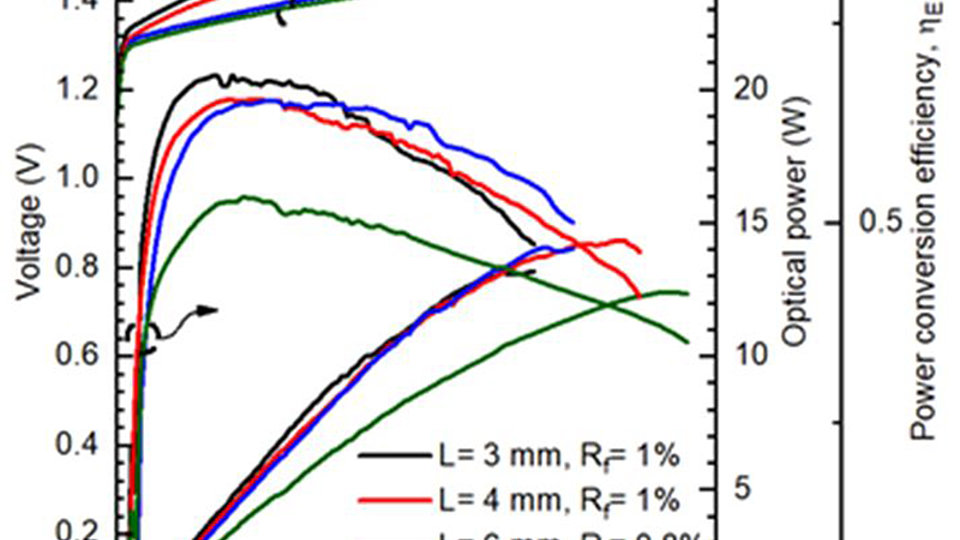

Fig. 2: The electro-optical characteristics of ASLOC lasers with = 90 µm, L = 3…6 mm under CW at 25 °C.

High-power diode lasers based on GaAs are the most efficient light sources for converting electrical input to optical power, making them most attractive to industry. Especially for material processing applications, high output power Popt with high conversion efficiency hE is been sought to reduce dissipated electrical power and lower cost in € per watt. Previous epitaxial designs followed a weakly asymmetric waveguide approach known as asymmetric large optical cavity (ASLOC) design. Although, ASLOC lasers operate with high peak hE, hE drops rapidly with bias due to thick p-waveguides. A thick p-waveguide leads to excessive optical loss and series resistance. Moreover, carrier leakage into the p-waveguide occurs. This can strongly limit power and efficiency of the laser.

FBH researchers have continued their work to understand and overcome power limiting factors, as recently presented at IEEE High Power Diode Lasers and Systems Conference (HPD) in Coventry, UK [1].

Two different approaches were used to increase Popt and hE at high Popt, focusing on broad area lasers with stripe width W = 90 μm emitting at wavelengths around l = 970 nm. First, the benefit of changes in the resonator length and facet reflectivity on efficient ASLOC designs from [2], were studied. Second, the advantage of alternative epitaxial layer designs – EDAS (extreme double asymmetric) and ETAS (extreme triple asymmetric) – were investigated for a fixed device geometry. Fig. 1 (a, b) shows exemplary refractive index and corresponding optical field profiles of the ASLOC and EDAS concepts, respectively.

In a first step, diode lasers with resonator lengths of L = 3, 4 and 6 mm were fabricated using the selected ASLOC design by following standard laser processes before being cleaved and facet passivated. The front and rear facets of lasers are next coated with dielectric layers, with Rf = 1% and Rr = 98% reflectivities, respectively for L = 3 and 4 mm. 6 mm long lasers were fabricated with Rf = 0.8% and 20% reflectivities. All lasers were mounted epi down using gold tin (AuSn) on expansion matched copper tungsten (CuW – 10:90) carriers. Devices with L = 4 mm were mounted and tested on free-standing CuW screening submounts (SSM). Devices with L = 3, 6 mm were first mounted onto CuW submounts that were subsequently mounted onto a conductively cooled package. All devices were tested under continuous wave (CW) conditions at a temperature of 25 °C.

Fig. 2 shows the electro-optical characteristics of the ASLOC lasers. For L = 3 mm, high peak hE = 68% is observed at Popt = 5 W, with peak Popt = 13 W and η (12 W) = 57%. Devices with L = 6 mm and Rf = 0.8% show much reduced series resistance and lower Rth (measured Rth = 4, 3, 2 K/W for L = 3, 4, 6 mm respectively), but operate with only marginally improved hE and Popt (peak hE = 65% at Popt = 8 W, peak Popt = 14 W and hE (12 W) = 59%). Even if hE is enhanced at high L, maximum Popt is limited by longitudinal spatial hole burning (LSHB). The impact of LSHB is diminished using high Rf, for flatter longitudinal optical field profiles, and devices with Rf = 20% saturate at higher currents (increased from 18 to 23 A at L = 6 mm), consistent with high LSHB.

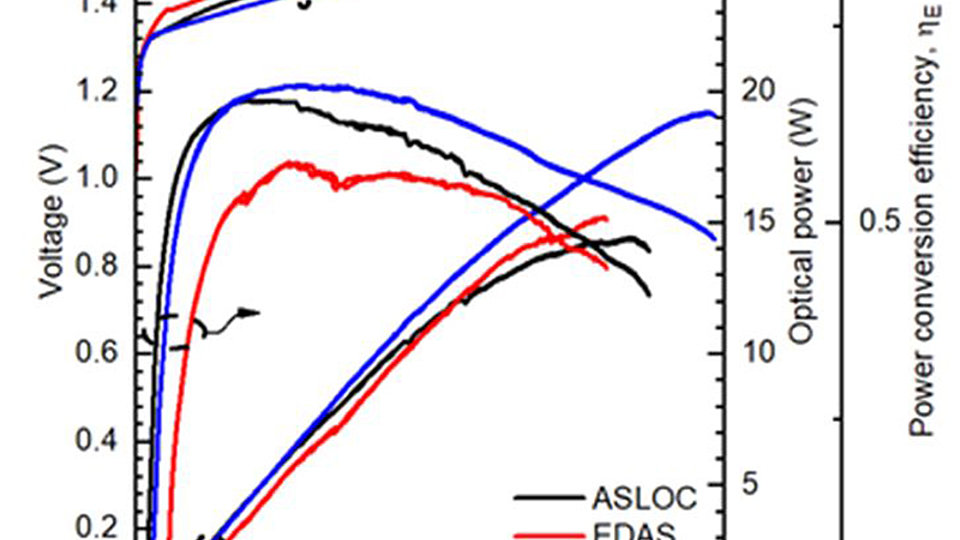

In a second step, lasers with L = 4 mm are compared that use single quantum well ASLOC (from [2]), EDAS (from [3]), and ETAS (from [4]) designs. After standard processing, facets were passivated and coated with Rf = 1%, Rr = 98%, then mounted epi-down onto SSM. Fig. 3 compares the electro-optical performance at 25 °C under CW operation. Lowest peak efficiency is observed for the EDAS design due to high threshold current caused by a low optical confinement factor G. However, the light-current curve remains linear to higher currents (less saturation, peak Popt = 15 W) and improved compared to the ASLOC design (peak Popt = 14 W). The combination of increased G and thin p-side (combined with a fine-tuned doping profile for low resistance) leads to the ETAS design having highest overall performance, with peak hE = 67% at Popt = 6.7 W, peak Popt = 19 W and hE (12 W) = 66%. Overall, enhanced vertical layer designs show stronger benefit for hE and Popt than changes to L or Rf.